Leg Breaker

I bought an aluminum 1‑1/32˝ bore master cylinder last year and discussed with you the very high pedal effort required to stop the car. I ended up putting a 15/16˝ cast iron master cylinder on it and pedal effort was lower. The car was drivable, but I was still not happy with the effort required (my 18-year old son races the car, and he is much stronger, so he was comfortable with the car). I’m a mechanical engineer, so I know (or at least I think I know) how much effort is required to stop a car. I was getting ready to start measuring

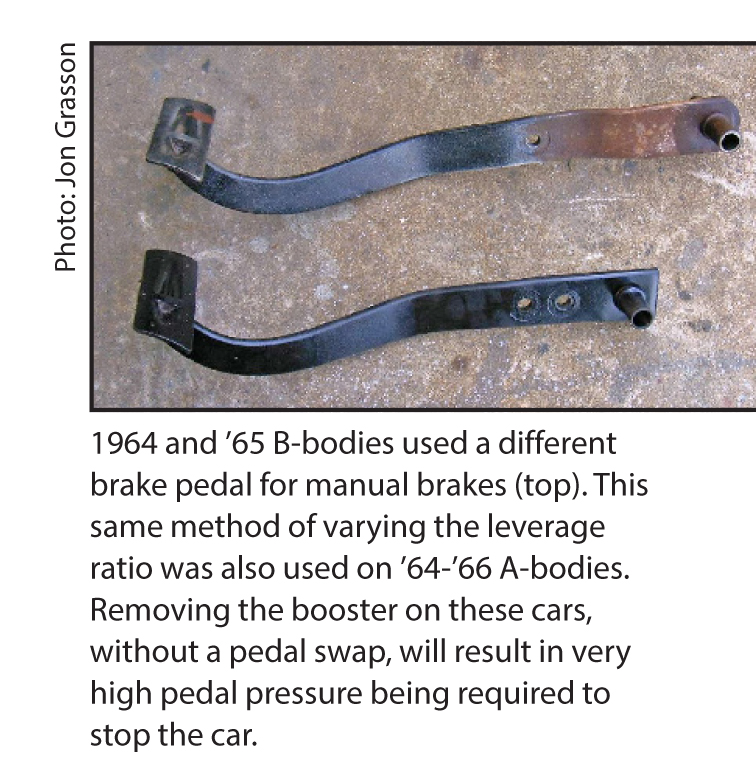

system pressures, when I stumbled on the desired brake pedal ratio for manual brake cars (6:1). The ‘64 Plymouth that we have measured 3:1. I found a member on Moparts that had an original manual brake

car and the pedal was noticeably longer (from the pivot to the brake pushrod attachment; see attached photo). So, if you get any complaints about pedal effort on master cylinder swaps, have the reader check the pedal ratio.

This is one of those areas that just seems

to have slipped by. From your pix, we can

see that your ‘64 B-body manual brake pedal

is radically different from the PB pedal. It

mounts higher so the pedal height (vertically)

is maintained. The vast majority of muscleera

Mopars use the same pedal for PB and

MB, the shorter travel and pedal closer to

the floor on the PB cars was made up in the

booster linkage.

Researching the factory parts catalogs

back to 1962, I find that only ’64-’65 B-bodies,

and ’64-’66 A-bodies used this differentpedal-

PB/MB arrangement. (Even ’62-’63

B-bodies were the same PB/MB).

Thanks for the tip.