Texas Steer

I’m putting a 1970 Coronet R/T (440-4,

non-A/C) back to dead stock. One of the

things the previous owner had done was to

remove the power steering. Luckily, he gave

me the correct (original) steering column and

the gearbox. But he didn’t have the pump or

brackets. I have found most of this stuff, all

supposedly correct, but I can’t see how the

pulley goes on the pump. The pulley has a

keyway slot, but the pump does not. And,

the pulley’s hole is a little too small to fit

over the shaft. I’m told that there are several

different arrangements. Which is right, and

how do make this all work and be correct?

Yes, this is a can of worms, to be sure.

First of all, in 1970, there were two different

pumps in use by Chrysler, and, yes, both

were used on big-block B-bodies. It’s an

either/or deal.

The first was referred to by Chrysler as

the “threaded hole shaft” pump, we now

refer to this by the vendor name: Federal (as

in Federal-Mogul). The Fed can be identified

by the round filler neck, the “tab” type, all steel

filler cap, and the pressure connection

on top, next to the filler neck. You could

always tell when these had oil in them, they

left their mark on the pavement. The second

one was called the “key slotted shaft”

pump, this is now called the Saginaw pump.

It has an oval filler neck, a smaller filler cap

at least partially made of plastic, and a

pressure connection on the rear of the

pump. In your case, the shaft should be

slotted for a woodruff key, and nut-retained

pulley.

But, it can get real complicated after that.

First, pulleys used in smallblock installations

had more offset than big block ones (see

photos.) Even thought the pumps were little,

if any different.

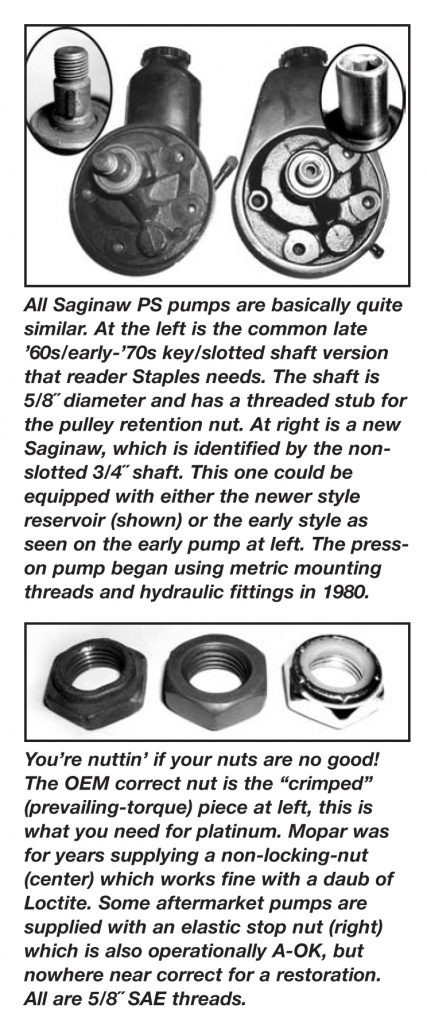

The Saginaw changed significantly in the

1976-’77 era. The shaft diameter went from

5/8˝ to 3/4˝, and the pulley was now press-on.

At a glance, they looked just like the

’67-’75 pump. Probably, this is the pump

you have.

Then, there was the later “metric”

Saginaw pump, introduced in 1980. It can

be recognized by the fact that there’s a very

short filler tube, the cap basically screws

right on to the reservoir. It uses a press-on

pulley. Aside from the metric mounting

hardware and pressure fitting, it’s interchangeable

with the early pumps.

If you want to make this car 100-point

correct, you need to find a correct

slotted/nutted Saginaw pump. These aren’t

too hard to find, most of the rebuilders offer

them. Then, you can use your hopefully correct

pulley (Mopar P/N 29851203—see

photo above for I.D. info.) If you don’t have

the correct pulley, Bouchillon Performance in

Hanrahan, SC (843-744-6559, www.bouchillonperformance.

com), offers an exact

reproduction. Their stock number is

BPE9016. Bouchillon, who helped us

research this, also offers something really

trick—a pulley that, even when scrutinized

pretty closely, looks like dead-stock, but

actually presses on to the later Saginaw

pumps and has the correct offset for the

popular (and easy) ’67-’72 big-block non-

A/C WP housing/alternator/pulley setups.

So you could just order Bouchillon’s P/N

BPE9017, and use the pump you’ve already

got.

Sharp eyed readers no doubt have added

two plus two. Yes, this means you could use

a brand-new, zero-problems Saginaw pump

on your ’70 if you wish (although this would

take it out of the resto category). All that

would be needed are a few metric bolts to

mount it, and either swapping the regulator

valve in the rear so you could retain your

original hose, or an ’80s pressure hose

(Diplomat, etc.). See photos/captions for

more details on this.

Bouchillon also offers all the other pulleys

(crankshaft, water pump, etc.) and brackets

for this installation if you need them.