Pattern Maker

I contacted you a few years ago about a noisy 741 pig I built using well used components. I swapped it out and I am finally getting back to the project for my 1966 Belvedere II. My first attempt had the pinion too far away so I tried setting it up again getting my best pattern with a 0.010Ëť pinion shim. Attached is a photo of the gear contact pattern. The rear is running very hot and I am getting a very loud resonance between 40 and 42 MPH (not there with the very loose pinion setup). Otherwise it was relatively quiet from zero to 80 MPH. The patterns are not too deep and everything feels smooth when I rotate the gear set by hand. The Yukon guide I used said to look at the coast side for used gears and not to worry about the heel to toe centering.

Note: I am running SSBC ’88‑’91 Thunderbird rear brakes with a 0.115˝ plate subbing for the drum brake backing plate. Foam and steel seals are in place, as is the differential axle shaft thrust spacer. E’berg specified zero axle shaft end play (tapered roller bearing) setting too.

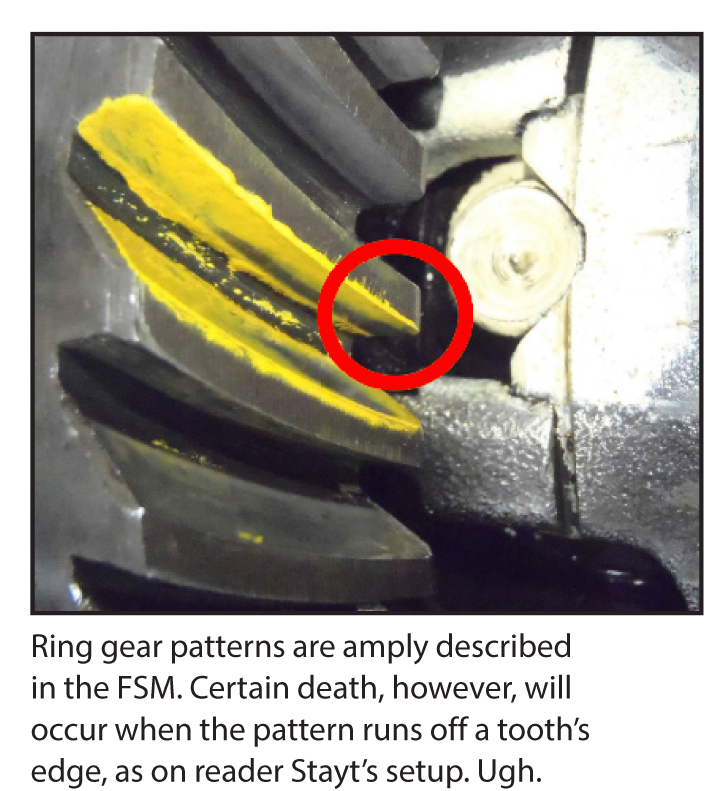

The pattern is horrendous. With the pinion basically crashing off the end of the ring teeth 3½ times per axle revolution, life will be very short indeed. Certain death for any ring and pinion happens when the power side runs off a cliff like that. While perfect centering isn’t a requirement (remember, there’s deflection under load, everything changes slightly), no pattern can ever (successfully) run off the end of a tooth. Even the coast side sucks, the pinion’s running off the top of the tooth.

For starters, you need a thinner pinion spacer, probably by at least 0.005˝.Your description of your spacer as 0.010˝ is intriguing—the thinnest made was 0.084˝, they went up to 0.100˝ in 0.002˝ increments. Any chance you are confusing pinion depth spacers (pressed on behind the “big” bearing) with the bearing preload shim pack?

If you take it apart immediately, you might be able to save it from total destruction, but it is unlikely that it will ever be totally quiet or 100,000-mile durable. It’s hurt—metal filings, etc.

I doubt I ever said zero axle bearing endplay; I do think the old factory specs. were too loose, but you should have 0.003 to 0.005” (checked after a short run-in period).