King of Darts

A 2008 Chrysler 300 in a 1970 Dart wrapper.

By Al Dente Photos by TheBruntBros

The amazing thing about this Dart mated with a 2008 Chrysler 300C is that it was not done by some hi-zoot custom shop but by an amateur for an auto restoration class project. Joe Lukes has “messed around” with his own and some friends’ rides in his home garage, but that were the usual fixes and performance upgrades. Nothing crazy. This is crazy.

Joe’s wrapper is a ’70 Sublime Dart because that’s the car in which he dated his future wife. The 300C, a 2008 model, came from a Minnesota boneyard. It had front end damage, but the rest of the car, drivetrain, rear suspension and interior were all good. One problem that Joe, and others who’ve tried these late model conversions is that when Chrysler went to Datalink communication in ’07, you have to use everything out of the late

model donor, including the wheel speed sensors (you have to figure

out a way to make them work) so all the computers can play nice together.

Otherwise it won’t work and you’ll end up banging your head against the

garage wall—a good way to get your head as a feature in our sister publication, “Headache Action” magazine, but not your car in Mopar Action or some lesser rag. Or spend big bucks for a custom computer re-flash.

The 300 chassis was cut to fit. Outside of the ‘well is Dart while the inside is 300.

So, the first thing Joe did was take measurements. Putting the tape between the outside of the brake drums, gave Joe the width of the Dart. He measured the Dart’s wheelbase so he knew where the 300’s wheels would have to be positioned. The stock height from floor to roof told Joe that he’d have to lower the floor quite a bit to get the headroom he needed. That was the easy part. The 300 would require some serious surgery to fit under the Dart.

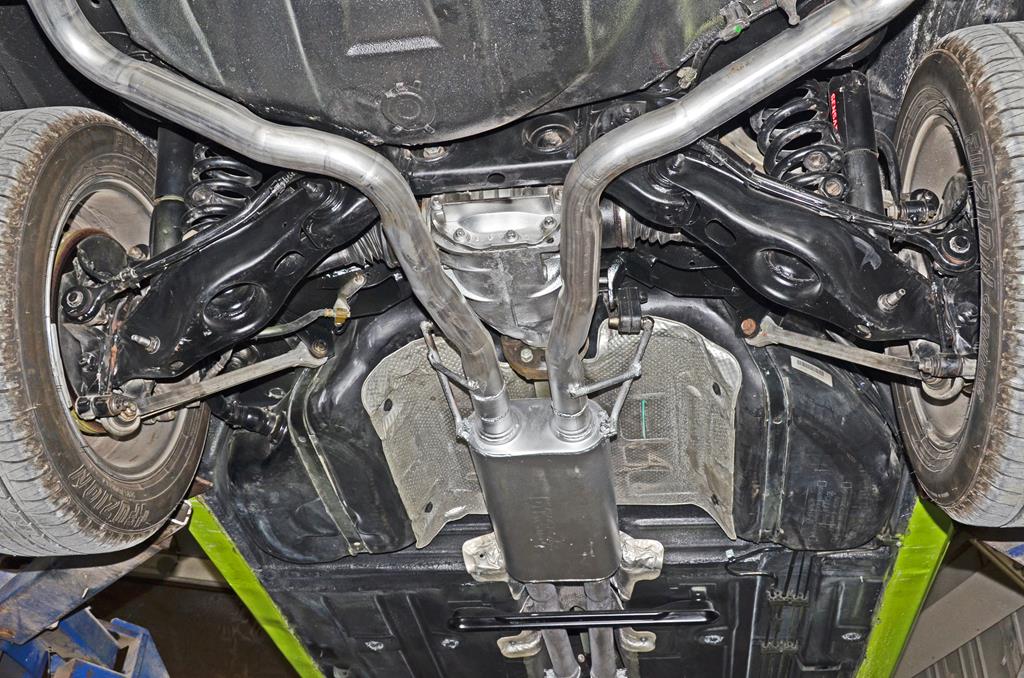

The track (distance between left and right wheels) would have to be narrowed which would involve modifying the front chassis cradle and narrowing the rear cradle. The 300 floor would come in for some Sawzall surgery being both narrowed and shortened.

“Under Restoration” category.

Joe took the Dart down to a bare shell with rockers but no firewall. He cut out the 300’s chassis/floor from the back bolt of the front cradle rearward to the back of the trunk. Leaving the front cradle in the stock position meant the Hemi would be correctly positioned in relation to the firewall. To fit the

300 firewall, Joe had to set it about 8 inches forward of the Dart’s stock firewall location. The firewall is narrowed and lengthened in height. Before the dash could be installed, all the 300’s HVAC ducts under the dash had

to be cut, shortened and rewelded. Joe ran tubes from the ductwork up to the vent and defrost outlets. The factory A/C and controls are retained.

The dash itself had to be narrowed and shortened taking 2 inches from each side, and 5 inches between the front of the dash and the windshield. He angled the vents in order to make the dash as wide as possible to fit

the glovebox and headlight switch. The vents alone were a 2-day job. All the stock climate control hardware is retained.

Joe added a second socket to the Dart taillight housing to give him a separate brake light.

Turning to the chassis, Joe shortened the floor 8 inches and narrowed it 3 inches so it would fit in the Dart’s rockers. The rear cradle was narrowed 6 inches with the leading edge of the rear cradle re-widend to accommodate the gas tank. The rear half-shafts were sent out to Moser Engineering to be shortened and resplined.

gave them a cardboard template and they worked from that. Strut towers are part of the Caddy modification. Joe squared them off, to look more like Chrysler than GM. Matt Reja came up with this neat engine cover with a dart theme. Strangely, none of the darts comes close to the bull’s eye. Guess he needs more practice.

Working from the firewall toward the rear, Joe fitted the 300 chassis in three sections. The first extends from the firewall to the front of the backseat. This is where Joe cut the 8 inches out of the floor—in front of the backseat. There’s still enough room so you don’t have to sit with your knees under your chin. The second section extends from the front of backseat to center of the hump to fit the rockers. Even though the floor was lowered to the very bottom of the rocker, the car lost about 2 inches of headroom compared to the 300, but Joe gained about 21/2 to 3 inches of headroom compared to the stock Dart was. Joe says when you start putting modern

seats in old cars the first thing you run out of it headroom, so he wanted to get it as low as possible. The 300 seats bolted right in, narrowing the floorpan didn’t affect the front seat position at all. Even the carpet almost

fit perfectly. The door panels are Dart.

welded ’90 Caddy DeVille frame rails under and inboard on the cradle so he could

narrow the track 6 in. by sectioning the cradle and shortening the outer tie rod ends 3 inches

each. Joe machined his own spindle to mate the Caddy suspension to the 300 hub which mounts

the wheel sensor and tone ring.

The rear seat bottom or floor couldn’t be altered because of the gas tank which fits up into the floor. The seatback had to be cut down in height because keeping the stock angle would have had the seatback poking out

the backlight about 6 inches.

The only mechanical parts of the 300 that were modified were the half-shafts and the front suspension. All the wiring is factory. Joe had to modify the headlights because the 300 had dual headlights and the Dart has single headlights. He cut the harness and wired it into a one bulb and did the same for the taillights. The 300 uses separate bulbs for turn signals and brake lamps, and a stock Dart just has one bulb for all of them. Joe drilled a hole

into the taillight housing and used panel bond to glue another socket in there which he used just for his brake lamp. So there are two bulbs instead of one.

When it came time to turn the key, Joe wasn’t sure what would happen. Would it start? Would it blow up? Would Tim Costello from “Mopar Collectors Guide” pop out of the woodwork with his camera to

try and scoop us?

have had to enroll in Auto Restoration The 300’s dual headlight wiring was modified to fit the Dart’s single beam.

floor had to be lowered to the bottom of the Dart rockers in order to fit both front and rear seats with adequate headroom.

It turned out to be a nonevent. The Hemi fired right up just like it did for the previous owner before his car got bashed. Joe has clocked some 4500 miles

with nary the slightest problem, including the 150 or so going back and forth on a stretch of road so TheBruntBros could get at least one moving shot that was in focus (Joe billed our publisher for the gas).

Needless to say, Joe got a passing grade in his auto restoration class. We can’t wait to see what he does next in his Rocket Science 101 class. He just may wind up with the fastest Dart on, or off, this planet.