The Seal Deal

Please recommend a high quality thread

sealant to use on the head bolts of my 1986

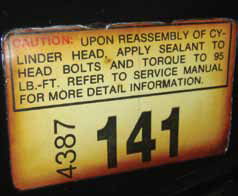

W250’s 318. The decal on the valve cover

makes it sound like this is important.

(Answer):

I have never used anything but light oil,

so that sticker really threw me a curveball.

Sure enough, I did find some reference to

sealer application in some 80s FSMs (but

not all). No mention as to why, though

you’d have to assume at least some holes

were wet (into the water jacket). I typically

have at least a few 340 or 360 blocks lying

around but have none at the moment to

inspect. Anyway, I put this by Chrysler

Engineering, including several retired

guys, and one current who is one of the

sharpest individuals I have ever met – Dick

Winkles. The following is a synopsis of his

and their – answers:

One engineer mentioned that his 1980

service manual recommended Mopar

Lock N’ Seal, P/N 4057989, and a final

torque of 105 ft-lbs., yet another one

wrote: “ I have a 1980 Dodge Truck service

manual and it doesn’t say to put anything

on the threads at all. It does say to “Coat

new gaskets lightly with number 1057794

[Mopar Perfect Seal, a gasket cement]

sealer and install on cylinder block. Then

install cylinder head bolts, torque to 50

ft-lbs, then 105 ft-lbs. No mention of thread

sealer or oil on the threads.”

Another said: “…Teflon sealer on the

head bolts. He should also look very

carefully at the block deck between the

head bolts and the water jackets because

those blocks liked to crack. Can’t really

remember what years these blocks were

used. With the heads off you can see that

the bolt holes are wet. With the engine

assembled I don’t remember if there is

any tell-tale signs other than the decal.”

Another fellow wrote back: “I have a 1983

318 that I recently rebuilt. It’s true. The

head bolt bosses, all but a couple are wet.

I couldn’t believe how many were wet and

[that] we would do such a thing, but we

did. We had a program back in the day to

make a lightweight LA engine block and

the head bolt bosses were reduced to take

weight out and they were through and wet.

I experienced this first hand with a 1983

318 engine.”

Dick himself wrote: “The light weight

‘A’ engine, or ‘LA’, had wet head bolt holes

other than the race and T/A blocks. In a

perfect world, the ‘LA’ head bolts didn’t

technically need sealant since the head

gaskets sealed around the head bolt anyway

– so it wasn’t recommended for many

years. Rather, oil was used to achieve a

more accurate torque reading. Sometime,

maybe late 70s or early 80s, sealant

was recommended to probably reduce

the possibility that coolant could get by

the head gasket and leak internally to the

crankcase or externally (the EPA/CARB

may have had a hand in this to reduce the

chance that any coolant could be lost) to

the environment. In my opinion, I’d use the

sealant. Just be mindful that it will affect

the true torque reading, I’d probably use

a high side head bolt torque like the 105

lb-ft number since sealant will have higher

turning friction than oil.”

Basically, I concur. The sealant will do

no harm if it is superfluous, and could prevent

a coolant leak if it is, in fact, needed.

Interestingly, one engineer looked up

the part number of that sticker and said

the first year it was used was 1989!